Application of a Deep Bed Band Filter

A deep bed band filter is an all-round and reliable filter for filtration of fluids. The BELKI Deep Bed Band Filter can be used for many processing fluids, for example grinding fluids, coolants and degreasers. Dependent on the application and requirement a deep bed band filter can be added with a magnetic filter for fine filtration of magnetic particles, smaller than the mesh size of the filter media.

Operation of a Deep Bed Band Filter

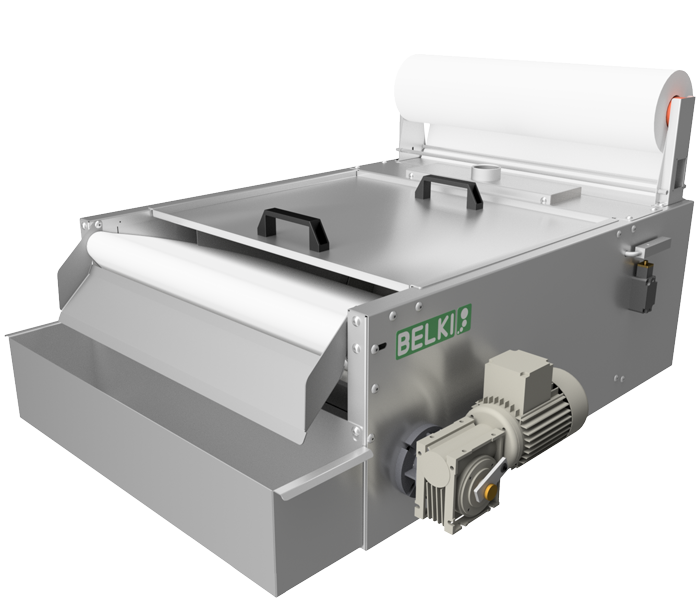

The fluid is filtered through a non-woven filter media; the quality is chosen after the specific application. The used filter media is separated from the filter cake and can be removed separately. The filtration becomes more efficient if the filter cake which is built on the filter media, is not washed away. In contrast the filter cake establishes a filter layer that retains small particles.

Advantages of a Deep Bed Band Filter

A BELKI Deep Bed Band Filter gives the best utilisation of the filter media. No leaks occur due to rupture or overflow. A BELKI Deep Bed Band Filter is designed in stainless steel which ensures low maintenance and a long lifetime.

Available in the following models: 4,5.60 - 5.10 - 7.10 -10.15 - 12.20

How can we help you?

Are you looking for a belt filter that is suitable for your requirements? Do you need an additional fine filtration of magnetic particles? Our competent team is always ready to advise you about belt filtration and to answer your questions. Please do not hesitate to contact us...

Working principle of Deep Bed Band FIlter

Range of Deep Bed Band Filters

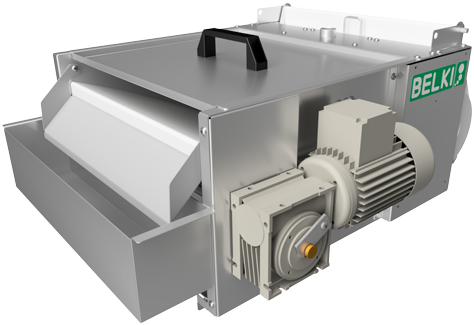

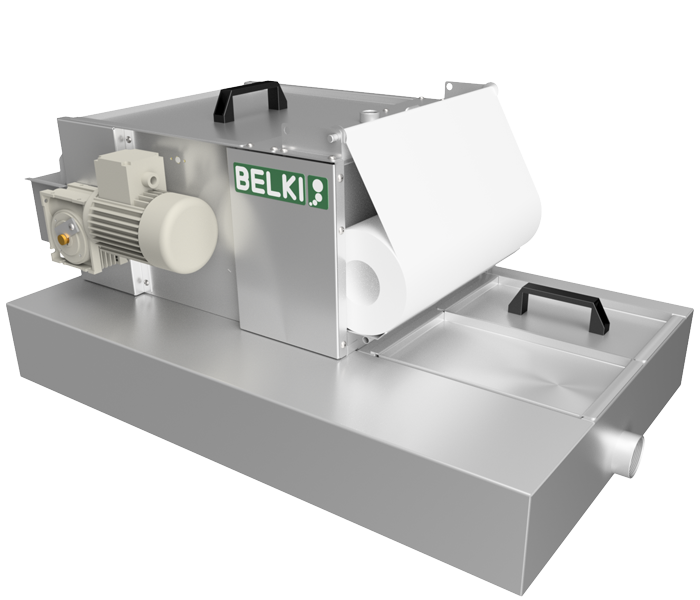

The compact filter is BELKI's smallest version of the deep bed belt filter made of stainless steel. With this technology almost all particles can be filtered out of process fluids. With a capacity of up to 50 l/min, this belt filter is the right choice for stand-alone machine tools and washing systems. A suitably selected filter fleece guarantees a high filter purity.

Compact filter 4,5.60

T60-000-000

Read more

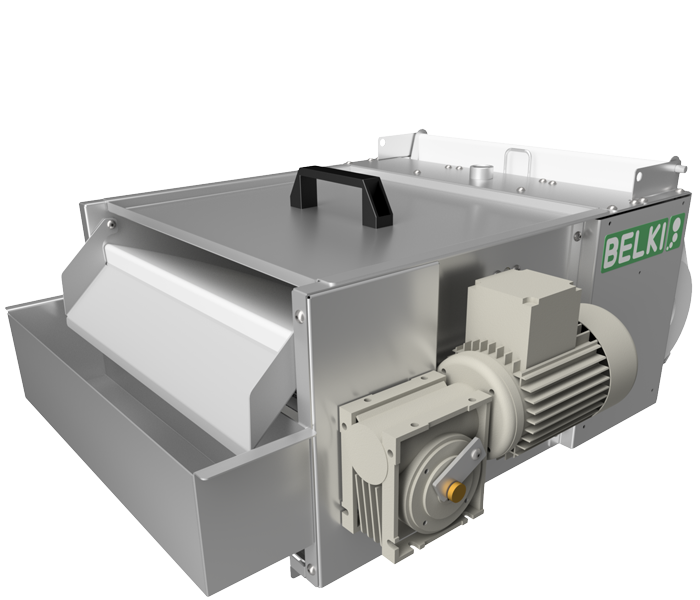

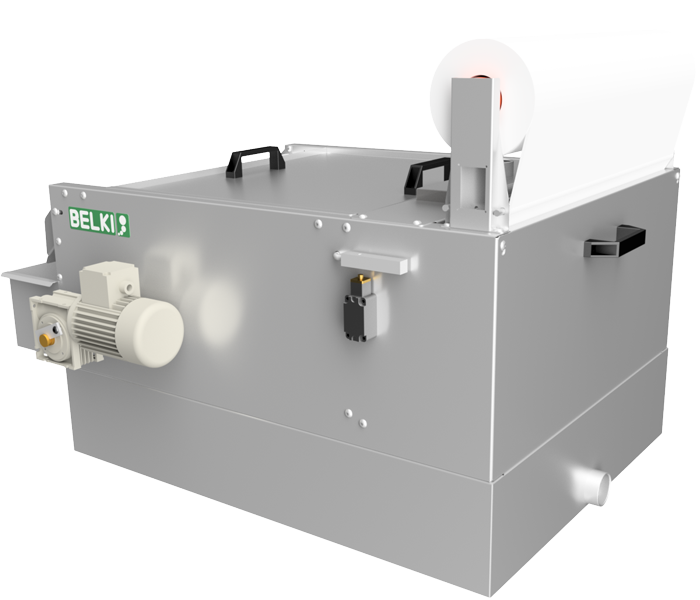

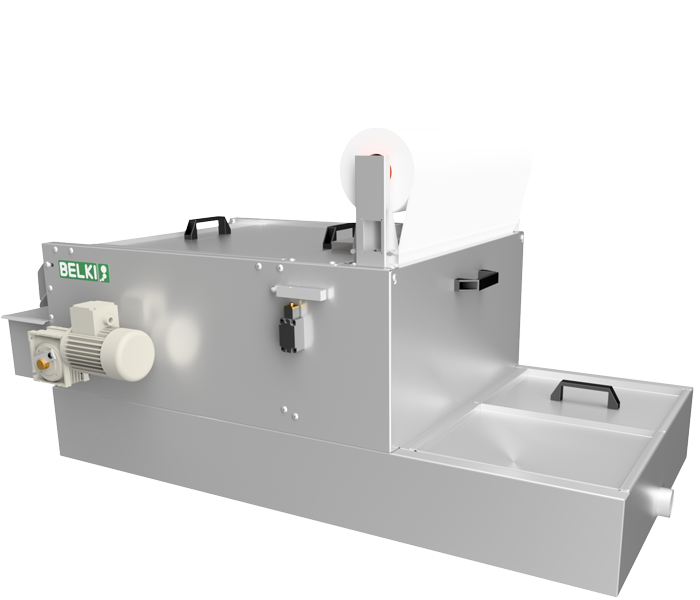

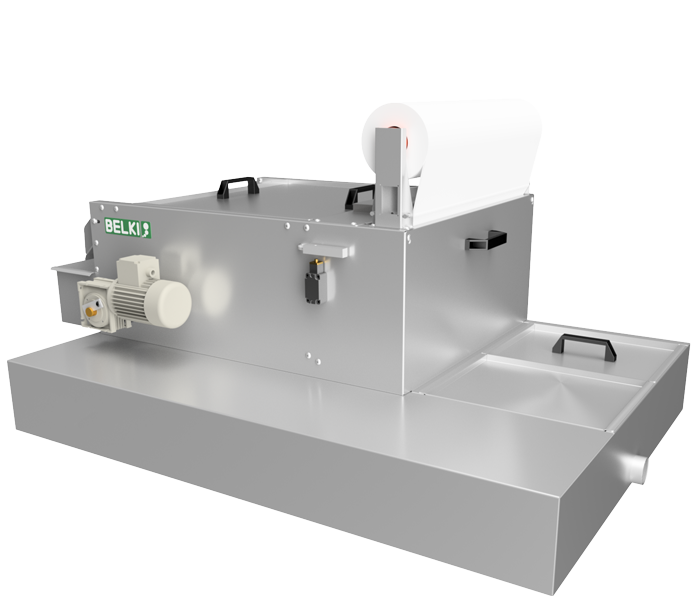

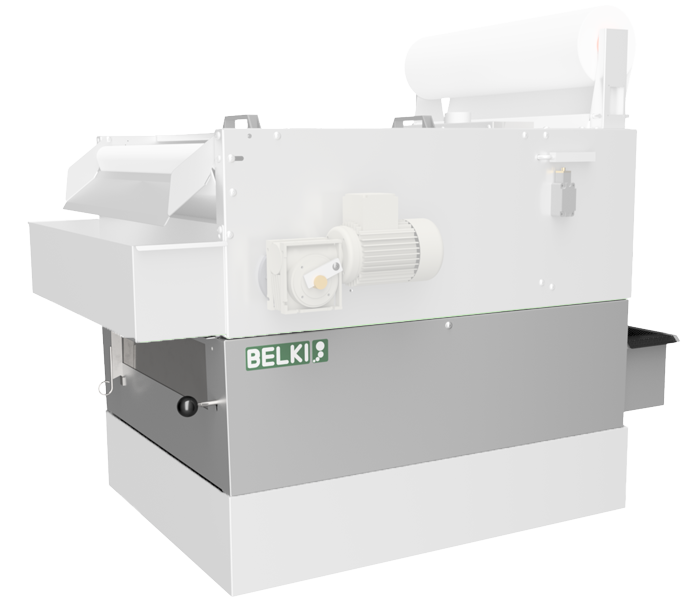

The BELKI deep bed band filters made of stainless steel are available in four different standard sizes. With this technology almost all particles can be filtered out of process fluids. With a capacity of up to 500 l/min, these band filters are the perfect choice for larger machine tools and central systems. A suitably selected filter fleece guarantees a high filter purity.

Deep bed filter 5.10-12.20

see the table

Read more

Technical specifications for Deep Bed Band Filters

| Type | Item nummer | Capacity (max l/min) | Filter surface (m²) | Degree of filtration (µm) | Acidity (pH) | Temperature (°C) | Connection (V/Hz) | Material | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4,5.60 | T60-000-000 | 50 | 0,2 | 20-80 | 5-10 | 20-60 | 3x400/50 | EN1.4301 | 817 | 621 | 363 |

| 5.10 | T33-000-000 | 150 | 0,35 | 20-80 | 5-10 | 20-60 | 3x400/50 | EN1.4301 | 1231 | 771 | 673 |

| 7.10 | T32-000-000 | 225 | 0,50 | 20-80 | 5-10 | 20-60 | 3x400/50 | EN1.4301 | 1274 | 941 | 673 |

| 10.15 | T15-000-000 | 350 | 1,0 | 20-80 | 5-10 | 20-60 | 3x400/50 | EN1.4301 | 1825 | 1250 | 796 |

| 12.20 | T72-000-000 | 500 | 2,0 | 20-80 | 5-10 | 20-60 | 3x400/50 | EN1.4301 | 2201 | 1458 | 794 |

Tank options for Deep Bed Band Filters

The tank category 1 (cat. 1) made of stainless steel for the compact filter serves as a collecting tank for the filtered process fluid. The filtered fluid flows via a drain into the clean tank at the machine tool. The cat. 1 tank fits exactly under the compact filter. With a volume of 42 l, the cat. 1 tank can also be supported by legs or delivered as a mobile device. Customized sizes available.

Tank cat. 1 for compact filter 4,5.60

Read more

The tank category 2 (cat. 2) made of stainless steel for the compact filter serves as a collecting tank for the filtered process fluid. The cat. 2 tank has a standard volume of 69 l. It offers space for pump, control cabinet and level monitoring. The filtered process fluid is pumped back to the machine tool. A maintenance cover allows easy cleaning. Customized sizes available.

Tank cat. 2 for compact filter 4,5.60

Read more

The tank category 3 (cat. 3) made of stainless steel for the compact filter serves as a collecting tank for the filtered process fluid. The cat. 3 tank has a volume of 98 l. It offers additional space for pumps, control cabinet and level monitoring. The filtered process fluid is pumped back to the machine tool. A maintenance cover allows easy cleaning. Customized sizes available.

Tank cat. 3 for compact filter 4,5.60

Read more

The tank category 1 (cat. 1) made of stainless steel for the deep bed band filters serves as a collecting tank for the filtered process fluid. The filtered process fluid flows via a drain into the clean tank at the machine tool. The cat. 1 tank fits exactly under the deep bed band filters. With a volume of up to 786 l, the cat. 1 tank can also be supported by legs. Customized sizes available.

Tank cat. 1 for deep bed band filter 5.10-12.20

Read more

The tank category 2 (cat. 2) made of stainless steel for the deep bed band filters serves as a collecting tank for the filtered process fluid. The cat. 2 tank has a volume of up to 971 l. It offers space for pump, control cabinet and level monitoring. The filtered process fluid is pumped back to the machine tool. A maintenance cover allows easy cleaning. Customized sizes available.

Tank cat. 2 for deep bed band filter 5.10-12.20

Read more

The tank category 3 (cat. 3) made of stainless steel for the deep bed band filters serves as a collection tank for the filtered process fluid. The cat. 3 tank has a volume of up to 1204 l. It offers additional space for pumps, control cabinet and level monitoring. The filtered process fluid is pumped back to the machine tool. A maintenance cover allows easy cleaning. Customized sizes available.

Tank cat. 3 for deep bed band filter 5.10-12.20

Read more

Magnetic filter for Deep Bed Band Filter

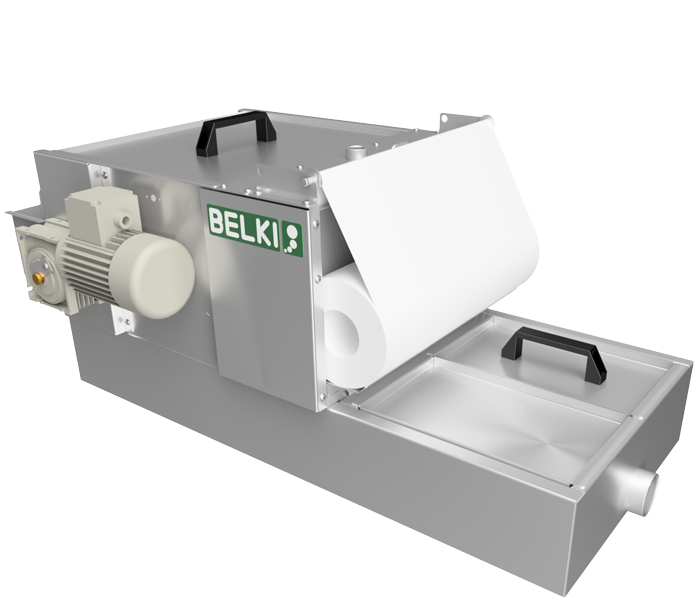

BELKI manual magnetic filter for compact filter and deep bed band filters enables ultra-fine filtration of ferritic particles. Equipped with powerful neodymium magnets, optimum filter purities are achieved. The filter cake is manually scraped into a sludge container with a scraper. All BELKI deep bed band filters can be retrofitted with the BELKI manual magnetic filter at any time.

Magnetic filter for deep bed filter

between filter and tank

Read more

Technical specifications for tanks for Deep Bed Band Filters

Basically, the BELKI tanks for deep bed band filters are manufactured in the material quality AISI304. A design in the material quality AISI316 is possible. Customized tank dimensions are also available on request.

| Tank category | Item number | Capacity (l) | Material | Length (mm) | Width (mm) | Standard height (mm) |

|---|---|---|---|---|---|---|

| Cat. 1 for 4,5.60 | T60-800-001 | 42 | EN1.4301 | 612 | 458 | 150 (adjustable) |

| Cat. 2 for 4,5.60 | T60-800-002 | 69 | EN1.4301 | 1004 | 458 | 150 (adjustable) |

| Cat. 3 for 4,5.60 | T60-800-003 | 98 | EN1.4301 | 1004 | 650 | 150 (adjustable) |

| Cat. 1 for 5.10 | T33-800-001 | 90 | EN1.4301 | 1012 | 593 | 150 (adjustable) |

| Cat. 2 for 5.10 | T33-800-002 | 134 | EN1.4301 | 1504 | 593 | 150 (adjustable) |

| Cat. 3 for 5.10 | T33-800-003 | 201 | EN1.4301 | 1504 | 893 | 150 (adjustable) |

| Cat. 1 for 7.10 | T32-800-001 | 161 | EN1.4301 | 1012 | 793 | 200 (adjustable) |

| Cat. 2 for 7.10 | T32-800-002 | 239 | EN1.4301 | 1504 | 793 | 200 (adjustable) |

| Cat. 3 for 7.10 | T32-800-003 | 329 | EN1.4301 | 1504 | 1093 | 200 (adjustable) |

| Cat. 1 for 10.15 | T15-800-001 | 423 | EN1.4301 | 1547 | 1093 | 250 (adjustable) |

| Cat. 2 for 10.15 | T15-800-002 | 571 | EN1.4301 | 2091 | 1093 | 250 (adjustable) |

| Cat. 3 for 10.15 | T15-800-003 | 743 | EN1.4301 | 2091 | 1421 | 250 (adjustable) |

| Cat. 1 for 12.20 | T72-800-001 | 786 | EN1.4301 | 2027 | 1293 | 300 (adjustable) |

| Cat. 2 for 12.20 | T72-800-002 | 971 | EN1.4301 | 2504 | 1293 | 300 (adjustable) |

| Cat. 3 for 12.20 | T72-800-003 | 1204 | EN1.4301 | 2504 | 1603 | 300 (adjustable) |