Application of a Paper Belt Filter

A paper belt filter is an all-round and reliable filter for filtration of fluids. The BELKI Paper Belt Filter can be used for many processing fluids, for example grinding fluids, coolants and degreasers, paint from spray booths, industrial wastewater, etc. It can also be used as a pre-filter for an ultrafiltration system.

Operation of a Paper Belt Filter

The fluid is filtered through a non-woven filter media; the quality is chosen after the specific application. As the filter paper clogged by impurities from the liquid, the liquid level rises. Only when the entire filter area is utilized, a floating ball activates an engine, which automatically feeds new filter paper. The used filter paper is collected in a waste box at the end of the system.

Advantages of a Paper Belt Filter

A BELKI paper filter ensures good filtration of process fluids, is extremely versatile and uses a low-cost filter material that keeps operating costs down.

How can we help you?

Are you looking for a paper belt filter that is suitable for your requirements? Do you need an additional tank with recirculation pump? Our competent team is always ready to advise you on paper belt filtration and to answer your questions. Please do not hesitate to contact us...

Range of Paper Belt Filters

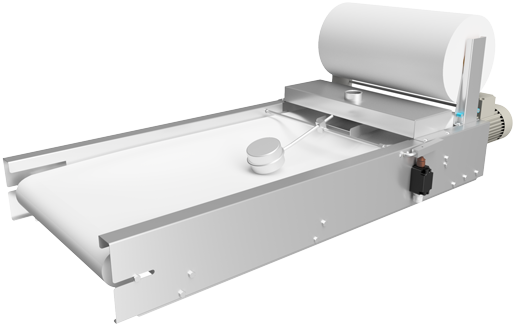

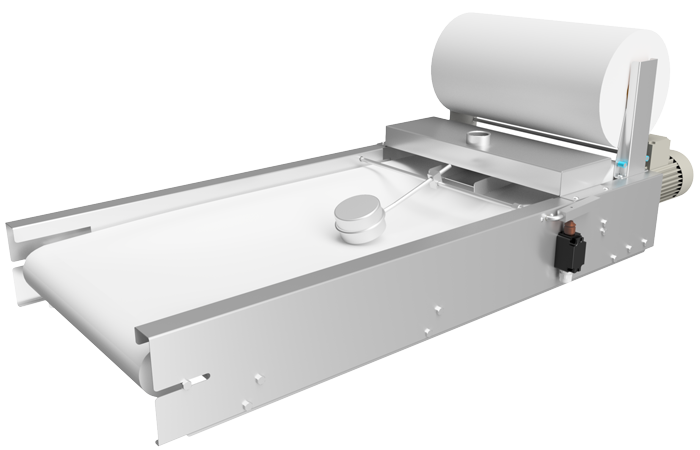

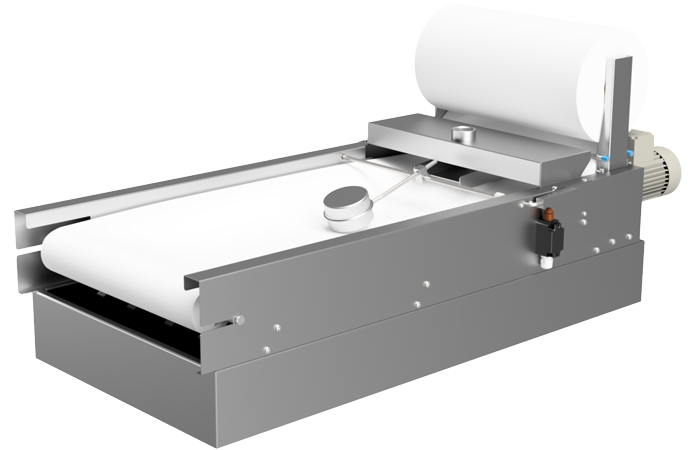

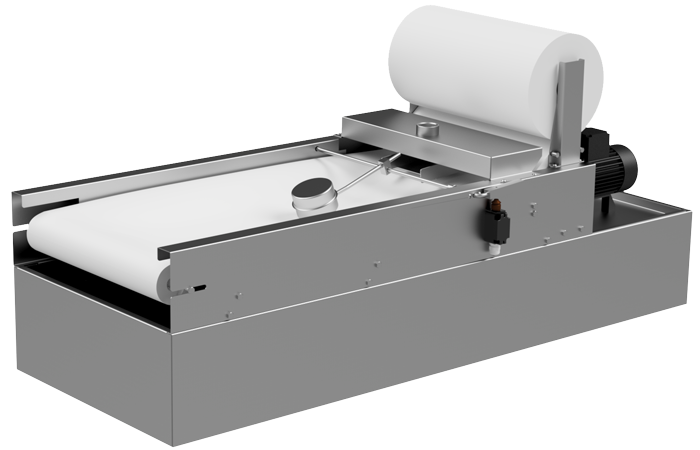

The paper belt filter made of stainless steel is built in different sizes (6.11-11.28HD) depending on the volume flow to be filtered. The flat design allows the filter to be used wherever the height of the processing machine or machine tank is limited. The paper belt filters are available in standard sizes up to 270 l/min. A suitably selected filter fleece guarantees a high filter purity.

Paper belt filter 6.11-11.28HD

see the table

Read more

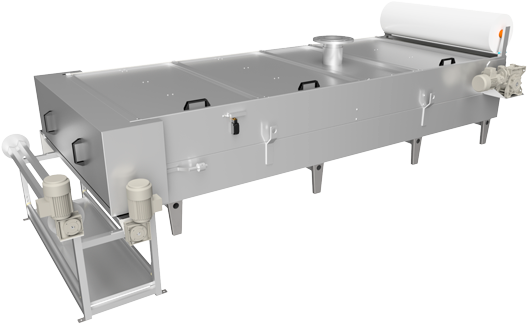

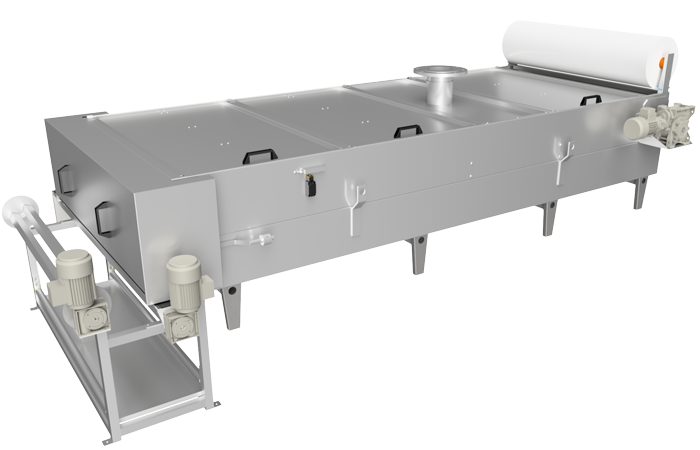

The paper belt filters (13.35HD-13.50HD) made of stainless steel are designed for large volume flows depending on the medium to be filtered. The filters are designed so that filter fleece and sludge can be disposed of separately. The sludge is led out sideways via an auger and the used filter fleece is wound up. The paper belt filters are available in standard sizes up to 600 l/min.

Paper belt filter 13.35HD-13.50HD

see the table

Read more

Technical specifications for Paper Belt Filters

| Type | Item nummer | Capacity (l/min) | Inlet (”) | Material | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|---|---|---|

| 6.07 | T78-607-000 | 30 | 1 1/2" | EN1.4301 | 1090 | 613 | 508 |

| 6.11 | T78-611-000 | 50 | 1 1/2" | EN1.4301 | 1490 | 613 | 508 |

| 6.14 | T78-614-000 | 65 | 1 1/2" | EN1.4301 | 1790 | 613 | 508 |

| 8.11 | T80-001-000 | 70 | 2" | EN1.4301 | 1490 | 813 | 508 |

| 8.14 | T80-814-000 | 90 | 2" | EN1.4301 | 1790 | 813 | 508 |

| 8.18 | T80-000-000 | 120 | 2" | EN1.4301 | 2190 | 813 | 508 |

| 8.24 | T78-002-000 | 160 | 2" | EN1.4301 | 2790 | 813 | 508 |

| 8.28 | T78-000-000 | 190 | 2" | EN1.4301 | 3190 | 813 | 508 |

| 11.18HD | T63-001-100 | 170 | 2" | EN1.4301 | 2190 | 1102 | 585 |

| 11.28HD | T192-1125-100 | 270 | 2" | EN1.4301 | 3190 | 1102 | 585 |

| 13.35HD | T192-1335-100 | 450 | DN150 | EN1.4301 | 3580 | 1402 | 632 |

| 13.50HD | T192-000-010 | 600 | DN150 | EN1.4301 | 4880 | 1402 | 632 |

Tank option for Paper Belt Filter

The tank category 1 (cat. 1) made of stainless steel for the paper belt filters serves as a collecting tank for the filtered process fluid. The filtered process fluid flows via a drain into the clean tank at the machine tool. The cat. 1 tank fits exactly under the paper belt filters and can also be supported by legs on request. Customized sizes available.

Tank cat. 1 for Paper Belt Filters

Available for all paper belt filter types

Read more

The tank category 2 (cat. 2) made of stainless steel for the paper belt filters serves as a collecting tank for the filtered process fluid. The cat. 2 tank has a volume of up to 1610 l. It offers space for pump, control cabinet and level monitoring. The filtered process fluid is pumped back to the machine tool. A maintenance cover allows easy cleaning. Customized sizes available. Legs on request.

Tank cat. 2 for Paper Belt Filters

Available for all paper belt filter types

Read more

Technical specifications for tanks category 1 for Paper Belt Filters

Basically, the BELKI tanks category 1 for paper belt filters are manufactured in the material quality AISI304. A design in the material quality AISI316 is possible. Customized tank dimensions are also available on request. The cat. 1 tank fits exactly under the paper belt filters and can be supported by legs on request.

| Tank category 1 | Item number | Capacity (l) | Outlet ('') | Material | Length (mm) | Width (mm) | Standard height (mm) |

|---|---|---|---|---|---|---|---|

| Cat. 1 for 6.07 | T707-607-100-H250 | 110 | 2" | EN1.4301 | 821 | 615 | 250 (adjustable) |

| Cat. 1 for 6.11 | T707-611-100-H250 | 170 | 2" | EN1.4301 | 1221 | 615 | 250 (adjustable) |

| Cat. 1 for 6.14 | T707-614-100-H250 | 210 | 2" | EN1.4301 | 1521 | 615 | 250 (adjustable) |

| Cat. 1 for 8.11 | T707-811-100-H250 | 220 | 3" | EN1.4301 | 1221 | 815 | 250 (adjustable) |

| Cat. 1 for 8.14 | T707-814-100-H250 | 280 | 3" | EN1.4301 | 1521 | 815 | 250 (adjustable) |

| Cat. 1 for 8.18 | T707-818-100-H250 | 350 | 3" | EN1.4301 | 1921 | 815 | 250 (adjustable) |

| Cat. 1 for 8.24 | T707-824-100-H250 | 460 | 3" | EN1.4301 | 2521 | 815 | 250 (adjustable) |

| Cat. 1 for 8.28 | T707-828-100-H250 | 530 | 3" | EN1.4301 | 2921 | 815 | 250 (adjustable) |

| Cat. 1 for 11.18HD | T707-1118-100-H250 | 440 | 3" | EN1.4301 | 1754 | 1113 | 250 (adjustable) |

| Cat. 1 for 11.28HD | T707-1128-100-H250 | 690 | 3" | EN1.4301 | 2754 | 1113 | 250 (adjustable) |

| Cat. 1 for 13.35HD | T707-1335-100-H250 | 1000 | DN150 | EN1.4301 | 3104 | 1402 | 250 (adjustable) |

| Cat. 1 for 13.50HD | T707-1350-100-H250 | 1510 | DN150 | EN1.4301 | 4604 | 1402 | 250 (adjustable) |

Technical specifications for tanks category 2 for Paper Belt Filters

Basically, the BELKI tanks category 2 for paper belt filters are manufactured in the material quality AISI304. A design in the material quality AISI316 is possible. Customized tank dimensions are also available and the tanks can also be supported by legs on request. The cat. 2 tank has a volume of up to 1610 l. It offers space for pump, control cabinet and level monitoring. The filtered process fluid is pumped back to the machine tool. A maintenance cover allows easy cleaning.

| Tank category 2 | Item number | Capacity (l) | Outlet ('') | Material | Length (mm) | Width (mm) | Standard height (mm) |

|---|---|---|---|---|---|---|---|

| Cat. 2 for 6.07 | T707-607-200-H250 | 170 | 1" | EN1.4301 | 1221 | 615 | 250 (adjustable) |

| Cat. 2 for 6.11 | T707-611-200-H250 | 220 | 1" | EN1.4301 | 1621 | 615 | 250 (adjustable) |

| Cat. 2 for 6.14 | T707-614-200-H250 | 260 | 1" | EN1.4301 | 1921 | 615 | 250 (adjustable) |

| Cat. 2 for 8.11 | T707-811-200-H250 | 290 | 1 1/2" | EN1.4301 | 1621 | 815 | 250 (adjustable) |

| Cat. 2 for 8.14 | T707-814-200-H250 | 350 | 1 1/2" | EN1.4301 | 1921 | 815 | 250 (adjustable) |

| Cat. 2 for 8.18 | T707-818-200-H250 | 420 | 1 1/2" | EN1.4301 | 2321 | 815 | 250 (adjustable) |

| Cat. 2 for 8.24 | T707-824-200-H250 | 530 | 1 1/2" | EN1.4301 | 2921 | 815 | 250 (adjustable) |

| Cat. 2 for 8.28 | T707-828-200-H250 | 610 | 1 1/2" | EN1.4301 | 3321 | 815 | 250 (adjustable) |

| Cat. 2 for 11.18HD | T707-1118-200-H250 | 540 | 1 1/2" | EN1.4301 | 2154 | 1113 | 250 (adjustable) |

| Cat. 2 for 11.28HD | T707-1128-200-H250 | 790 | 1 1/2" | EN1.4301 | 3154 | 1113 | 250 (adjustable) |

| Cat. 2 for 13.35HD | T707-1335-200-H250 | 1130 | 1 1/2" | EN1.4301 | 3604 | 1402 | 250 (adjustable) |

| Cat. 2 for 13.50HD | T707-1350-200-H250 | 1610 | 1 1/2" | EN1.4301 | 5104 | 1402 | 250 (adjustable) |